OUR PRODUCTS

Where reliability

meets affordability

Understanding the principle of orthopaedics and ergonomics, we at Giaplus design state of the art implants using titanium and stainless steel for higher reliability, greater mobility and economical viability. Explore the plethora of products and choose Giaplus orthopaedic implants for swift functionality.

Orthopedic implants are medical devices that are surgically implanted into the body to replace or stabilize fractured or diseased bones, joints, or other skeletal structures. These implants are made of a variety of materials which include metal, ceramic, or plastic.

Orthopedic implants are used for a variety of purposes, replacing diseased joints, stabilizing fractured or broken bones to promote quick healing, fusing spinal vertebrae in cases of herniated discs or spinal stenosis.

There are many types of orthopedic implants, each designed for a specific purpose. The common types of orthopedic implants include joint replacement implants, fracture fixation implants, spinal implants, trauma implants, dental implants, maxillofacial implants, etc. Browse our orthopedic implant categories listed below. GiaPlus also offers a complete product catalog in PDF file format which includes specifications and technical information.

Orthopedic implants are used for a variety of purposes, replacing diseased joints, stabilizing fractured or broken bones to promote quick healing, fusing spinal vertebrae in cases of herniated discs or spinal stenosis.

There are many types of orthopedic implants, each designed for a specific purpose. The common types of orthopedic implants include joint replacement implants, fracture fixation implants, spinal implants, trauma implants, dental implants, maxillofacial implants, etc. Browse our orthopedic implant categories listed below. GiaPlus also offers a complete product catalog in PDF file format which includes specifications and technical information.

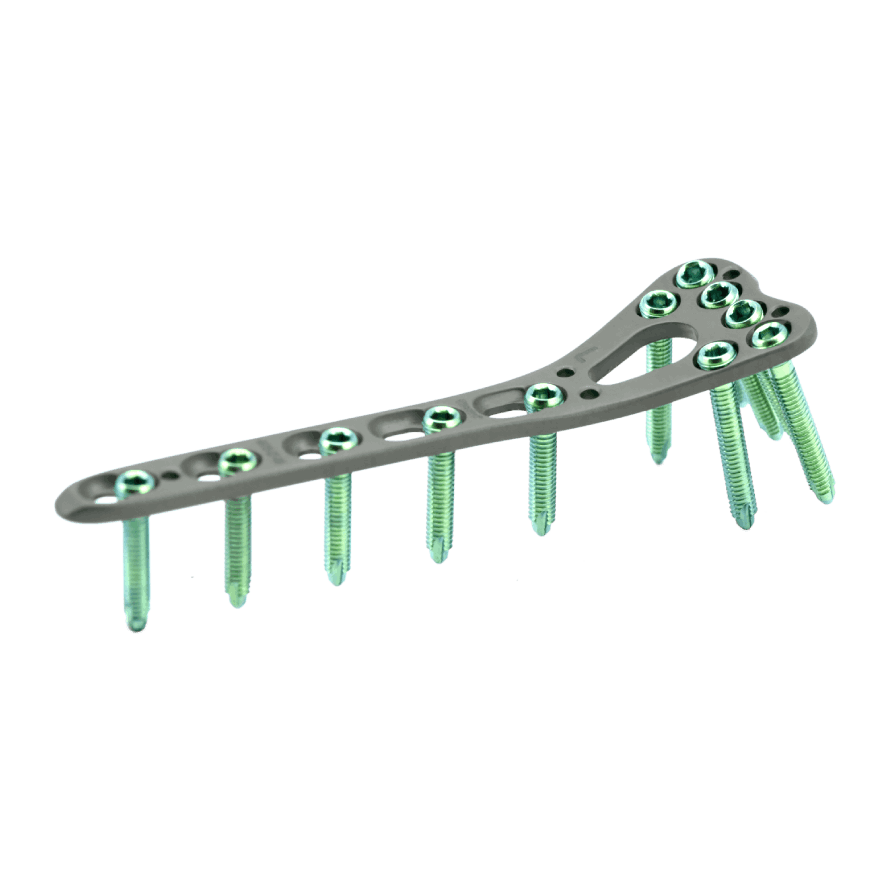

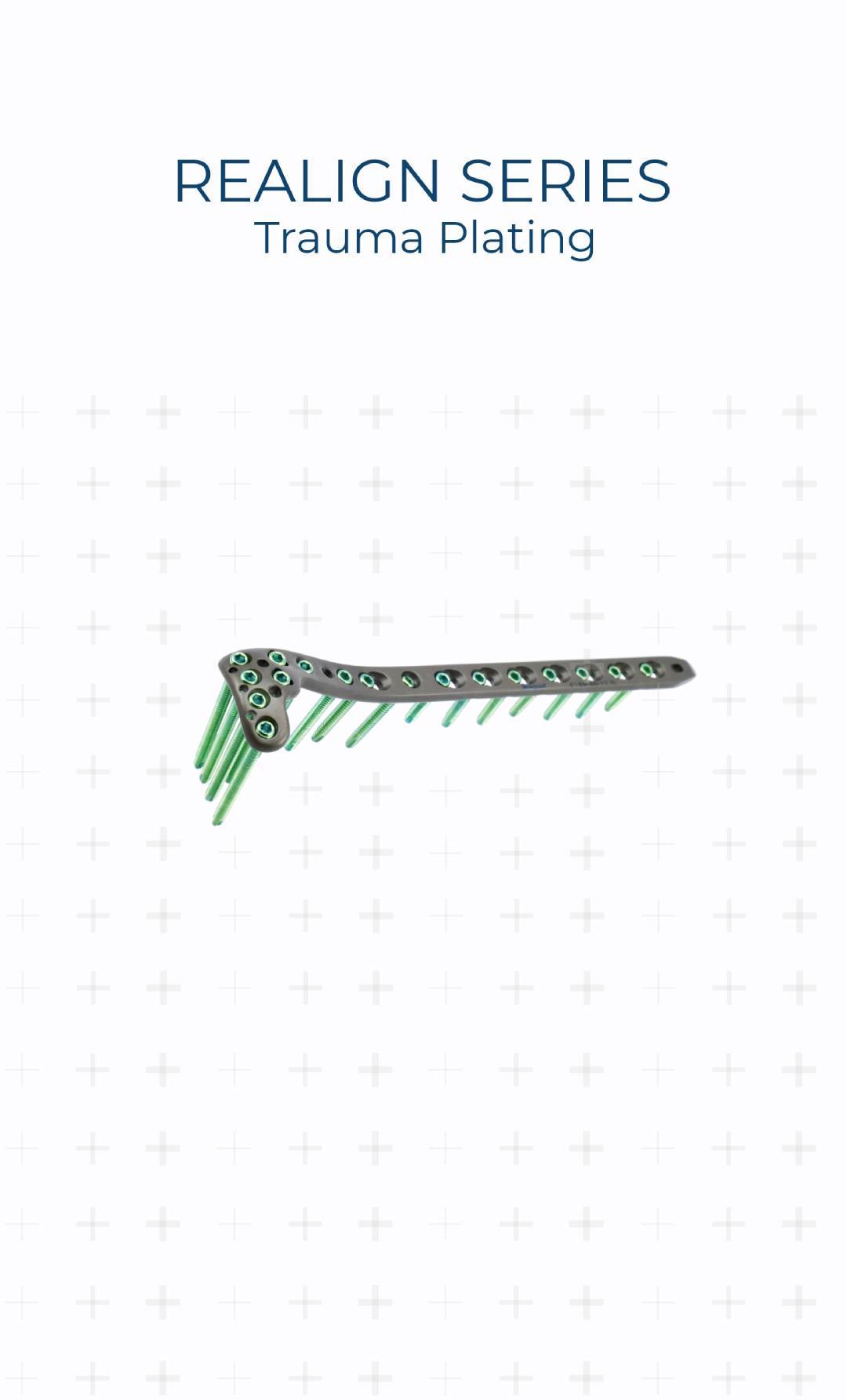

Trauma plating is a type of implant used to fix bone fractures and injuries. The plate is attached to the bone using screws, and it provides stability and support to the bone as it heals.

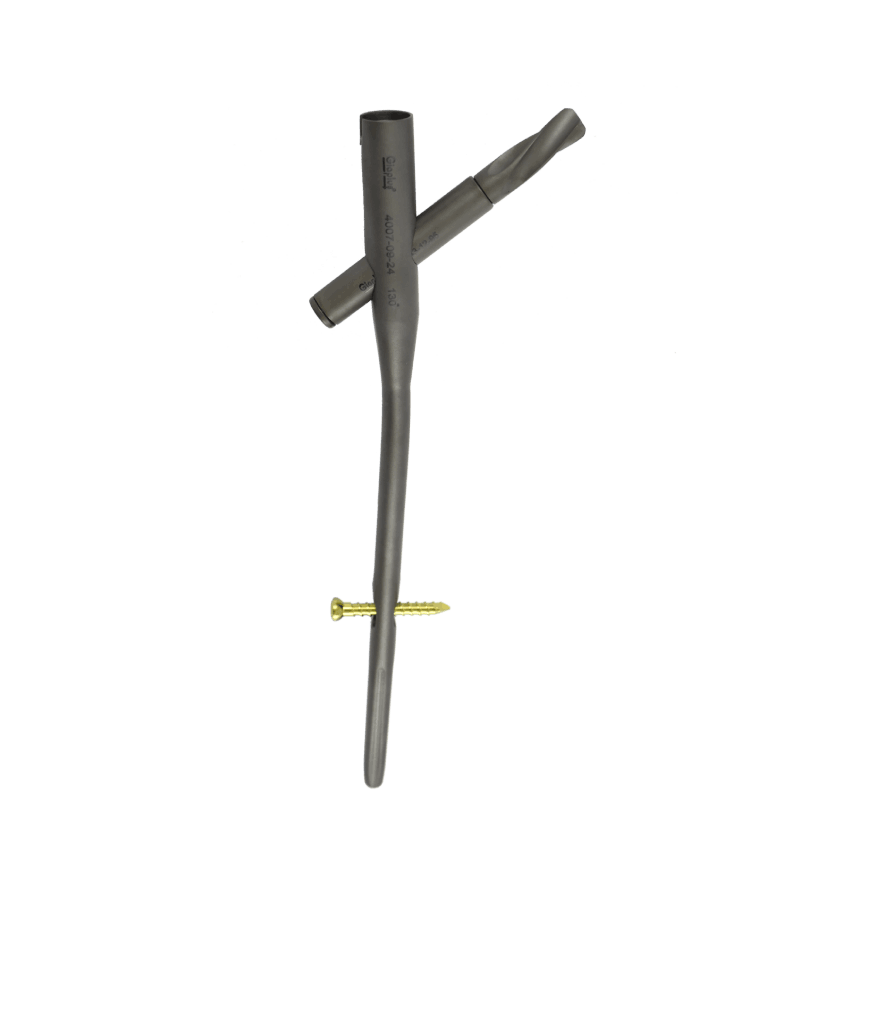

An interlocking nail is a type of implant used to fix long bone fractures, such as those in the femur or tibia. The nail is inserted into the bone and held in place with screws, providing stability and support during the healing process.

Pelvis plating is a type of implant used to stabilize fractures of the pelvic bone. The plate is attached to the bone using screws and provides stability and support during the healing process.

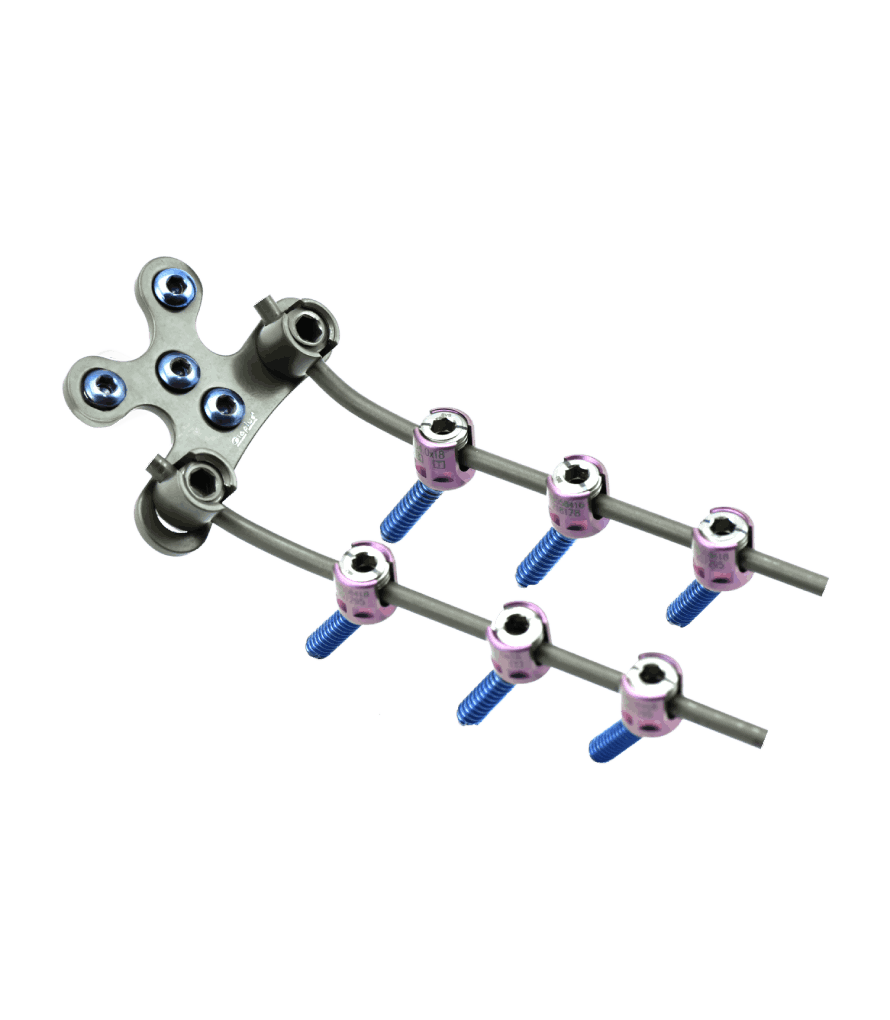

Spinal implants are used to treat spinal conditions, such as degenerative disc disease, herniated discs, and spinal fractures. They can include screws, rods, and cages, which are used to stabilize the spine and promote healing.

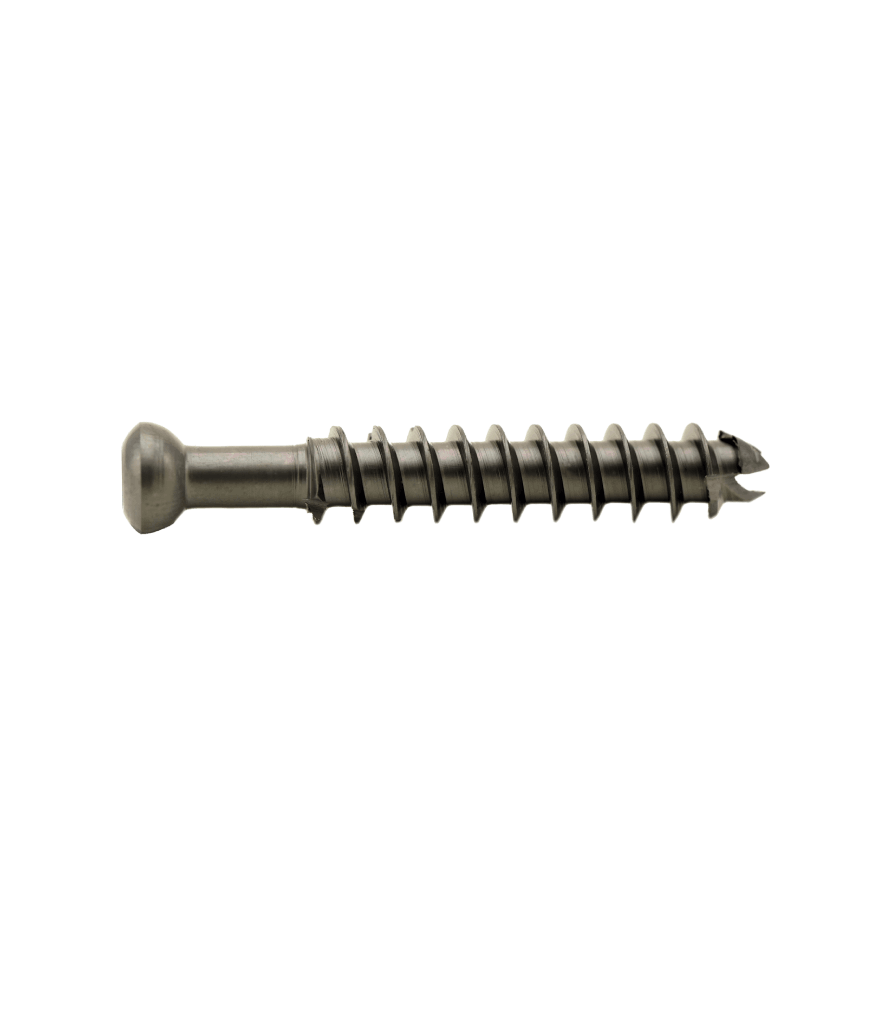

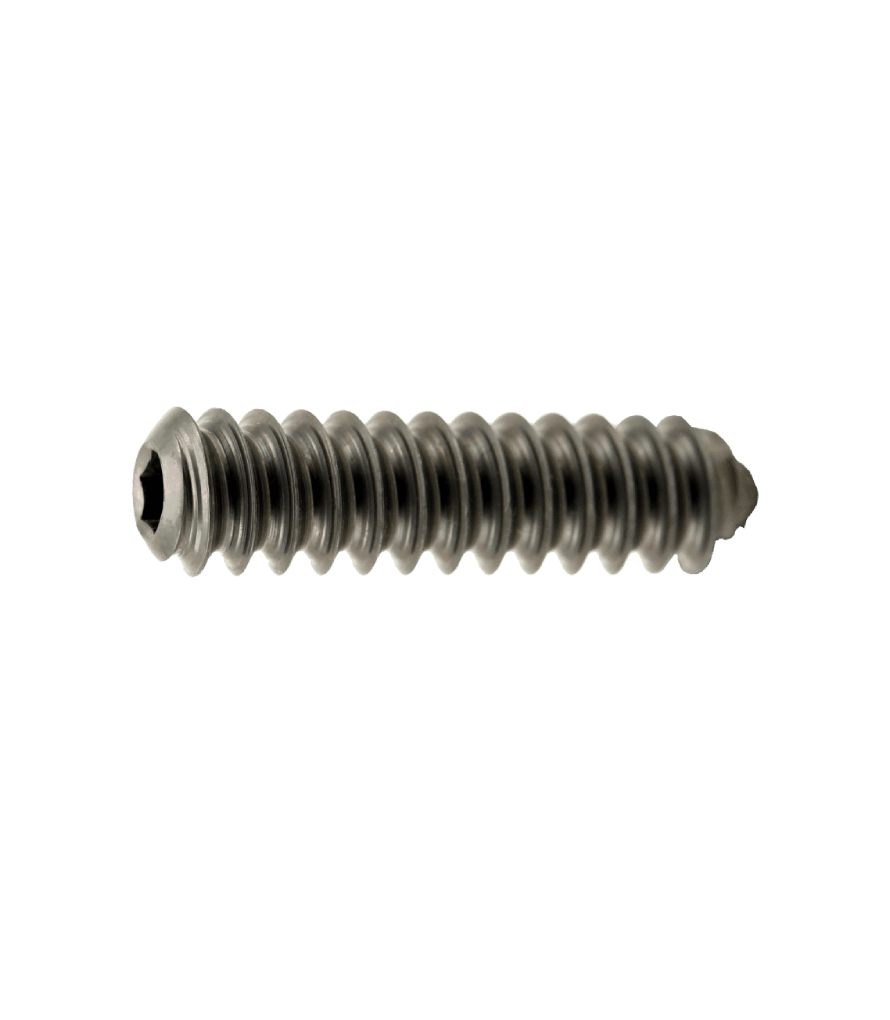

Orthopedic screws are used to fix bone fractures and injuries. They can be used with other implants, such as plates and nails, to provide stability and support to the bone during the healing process.

Arthroscopy implants are used to repair and treat joint injuries, such as those in the knee or shoulder. They can include screws, anchors, and sutures, which are used to stabilize and repair damaged ligaments and tendons.

Frequently Asked Questions

Orthopedic implants are used for a variety of purposes, replacing diseased joints, stabilizing fractured or broken bones to promote quick healing, fusing spinal vertebrae in cases of herniated discs or spinal stenosis.

Orthopedic implants are designed to provide long-term stability and support for the body, and in many cases, they do not need to be removed. However, there are situations where the removal of an orthopedic implant may be necessary, including infection, pain, discomfort, allergy or it is interfering with the patient’s ambulation.

The cost of orthopedic implants vary widely depending on various factors, such as the type of implant, material used, the complexity of the surgery, the location of the hospital, and the healthcare system. The cost of an implant may be covered by insurance or government programs depending on your insurance company and domicile.

Choosing the appropriate orthopedic implant involves a medical evaluation of the patient’s age, health, lifestyle factors, patient anatomy, type of injury, cost, availability of implants, long-term outcomes of surgery. The surgeon and patient will work together to choose the best implant based on above factors

Our orthopedic implants are designed and fatigue tested for achieving zero failure rates. The process starts with designing the implant using computer-aided design (CAD) software keeping into consideration the medical condition or injury being treated, size, shape, and material. Then the best material for the implant is selected based upon the quantum of stress it has to withstand which could be surgical grade stainless steel or titanium.

After the material selection, designs are sent to the production department for the manufacturing process which involves cutting, shaping, and polishing the implant using computer numerical control (CNC) machines and 3D printers. The manufacturing process may involve cutting, shaping, and polishing the implant to the precise specifications of the design. Last stages of manufacturing are rigorous testing, inspection, sterilization and contaminant free packing to exceed globally required standards for quality, safety, and performance.